|

創業家埃里克·里斯靠著教授新創企業學習大型跨國企業做事方式聲名鵲起,如今他又開始教大型企業向新創企業學習。 在耶魯讀本科時里斯就開始創業,后來又在不少公司工作過,讓他忍不住好奇為什么有些企業會成功,而有些會失敗。找尋原因的過程中,里斯發現了“精益化管理”的威力,這一概念首先因豐田等日本企業出名,核心論點在于企業的目標就是向客戶輸送價值,否則就是浪費資源。 在2011年出版的《精益創業》一書中,里斯將精益化管理的思路應用在創業上。他建議創始人少花點時間忙融資,搭建宏大的商業計劃,多注意征求反饋收集數據,確保產品能滿足真實需要,且能推動客戶的需求。里斯還更進一步,提出大型官僚化企業應該采取類似措施,方能保持進步維持增長。 《精益創業》已成為商學院重要教材,也成了暢銷書——目前銷量超過100萬本,里斯也為大大小小數十家企業提供咨詢。本月出版的新書《創業之術》(Currency/企鵝蘭登書屋,售價30美元)中,里斯歸納咨詢經驗,介紹了《財富》500強企業應該如何借鑒“創業式管理”的企業文化。在以下節選文本中,里斯講述了勸服具有125年歷史,30萬員工的巨頭通用電氣轉換思路的故事。——馬特·海默爾 |

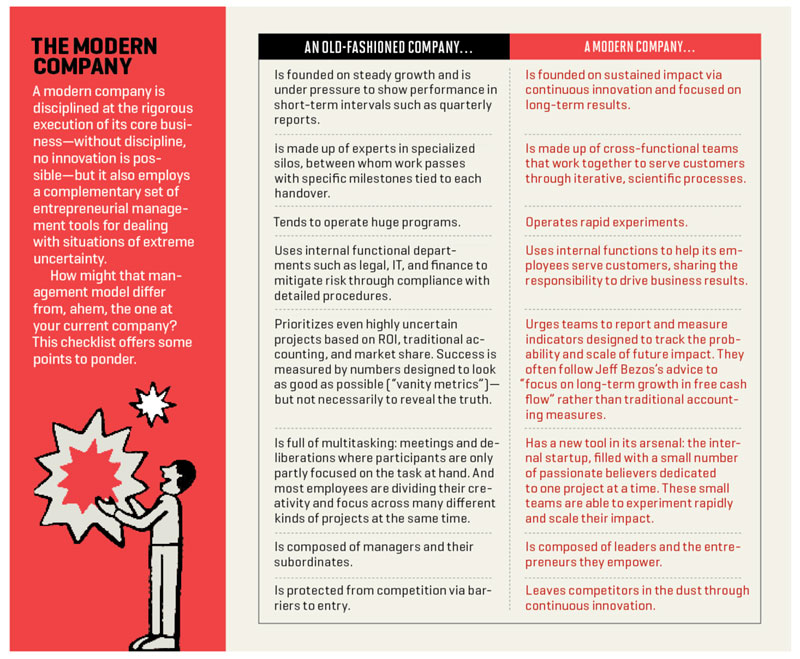

Entrepreneur Eric Ries rose to prominence by teaching ?startups how to adopt the best practices of big, global ?companies. Today he’s also teaching huge companies how to behave more like the upstarts. He began his entrepreneurial career while still a Yale undergrad, and his mixed track record at multiple companies stoked his curiosity about what ideas separated the winners from the losers. His exploration of that topic led Ries to embrace “lean management”—the concept, made famous by Toyota and other Japanese manufacturers, that any business process that isn’t focused on delivering value to the customer is, ultimately, a waste of resources. In his 2011 book, The Lean Startup, Ries applied lean-management thinking to entrepreneurship. He urged founders to spend less time chasing funding and building epic-scale business plans, and more time soliciting feedback and harvesting data to make sure the product they were building met a real need that would drive customer demand. Ries also went a step further—arguing that big, bureaucratic companies needed to adopt similar approaches to evolve and sustain their own growth. The Lean Startup became a business-school staple and a blockbuster—it has sold more than a million copies—and Ries has gone on to advise dozens of companies of all sizes. In a new book out this month, The Startup Way (Currency/Penguin Random House, $30), Ries draws on his experience to describe how Fortune 500 companies can adopt a culture of “entrepreneurial management.” In this edited excerpt, he recounts how he persuaded managers at General Electric (GE, -0.77%) , a 125-year-old, 300,000-employee behemoth, to embrace a different kind of thinking. —Matt Heimer |

圖片:Manfred Koh

|

夏日一個午后,一家大型美國企業的工程師和高管坐在龐大培訓中心的管理人員培訓教室里,討論著幾億美元的大生意。他們下一個五年計劃是開發新款柴油和天然氣發動機,目標是打入新市場,氣氛十分熱烈。新款發動機命名為X系列,從能源生產到機車動力很多行業都可以廣泛應用。 對在座人士來說整個計劃很明確,只有一位參會者例外,他之前根本不了解發動機和能源,也不懂工業產品生產,所以只能問些兒童繪本作家蘇斯博士可能問的初級問題: “做什么用的來著?船上?飛機上?海上還是陸地?還是火車上?” 在場的高管和工程師都忍不住嘀咕,“這家伙是誰啊?” 這個人就是我,而這家企業是通用電氣,美國歷史最悠久也最可敬的企業之一。我不是公司高管,背景不是能源不是醫療,跟通用電氣龐大的業務一點也不沾邊。我只是個創業者。 但那天,時任通用電氣總裁兼首席執行官的杰弗里·伊梅爾特和時任副總裁的貝斯·康斯托克邀請我去紐約科羅頓維爾,也即通用電氣培訓中心所在地,原因是他們對我在第一本書中提出的觀點很感興趣。我認為新創企業管理方式可適用于任何行業,不論企業規模大小,也不論身處何種經濟部門。他們認為通用電氣也要開始按照這些原則改變,最終目標是推動企業增長,提高適應能力,以及打造確保企業長期繁榮的制度傳承。 我從沒想過會參加那次會議,也沒預料到。剛工作時我是軟件工程師,后來開始創業。如果你印象中科技創業者就像個小孩,喜歡躲在父母家中地下室里鉆研,沒錯,我就是這樣的。我第一次嘗試創業是在互聯網泡沫時期,一敗涂地。我第一次出版大作是1996年,書名是《Java游戲編程的黑色藝術》,上次去亞馬遜網站看還有賣,99美元一本,從這些項目都看不出來之后我主要工作會變成宣傳新型管理方式。 我搬去硅谷后,發現很多企業成功和失敗的規律。我開始總結模式,研究如何激發創業精神。之后我開始寫,2008年開始在網上寫,后來集結成書,2011年出版了《精益創業》。 書中提出了當時看來比較激進的觀點。我認為新創企業應該理解為“在極端不確定情況下努力創造新產品和服務的人類組織。”這個概念有意提得比較泛,沒有明確企業的規模,具體形式(公司、非盈利組織還是別的什么),也沒指明行業和領域。在這個廣泛的定義下,任何人,不管官方職位如何都可以有創業精神。我認為創業家可以在任何地方——小企業、大巨頭、醫療系統、學校,甚至政府機關。只要人們勇于暢想并踐行新觀念,采用新工作方式,或將產品或服務拓展至新市場服務新客戶,都可稱為創業。 該論點也解釋了為何過去五年里我一直過著雙面生活。上午我經常跟大企業、領先市場的公司打交道,下午則主要見新創企業,從發展極為迅速的硅谷神話級公司到剛起步種子階段的小公司都有。他們問我的問題卻出奇一致: 如何鼓勵下屬像創業者一樣思考?如何保住現有客戶的同時為新市場打造新產品?如何營造擅長平衡現有業務與新增長點的經營文化? 通過向合作公司學習,我開始構思新作,主要關于不限于“起步階段”的管理規則,尤其適應于成熟企業甚至大型企業的。內容關鍵在于傳統管理與創業式管理如何完美結合。 內容主要是案例分析和通過各種渠道收集的經驗:有通用電氣和豐田之類知名跨國企業;有著名科技先鋒亞馬遜、Intuit和Facebook;有新一代發展迅速的新創企業,例如Twilio、Dropbox和愛彼迎;當然也有無數沒聽過的新新創企業。 通過互相合作,我發現在21世紀創業精神確實可能重振管理思路。這可不限于某個特定行業里的工作方式,而是各地人們工作或希望工作的方式。我稱之為創業之術。 通用電氣管理者選擇X系列發動機項目試水并非偶然。他們認為如果我能成功革新這個規模巨大又跨平臺合作的發動機項目,那么精益創業思路就能在全企業推行,從而實現多項業務中簡化工作流程的目標。 我在科羅頓維爾開完第一個會沒幾個小時,又去培訓中心另一個很像商學院的教室里,身邊都是X系列發動機開發各相關部門的工程師,各部門首席執行官,還有幾位負責跨部門業務級別很高的管理者,我這次拜訪正是他們邀請。 我們只想回答杰夫·伊梅爾特一直追問的問題:“為什么X系列發動機開發需要五年?” 我首先開腔,請X系列研發團隊梳理一下五年計劃。我的角色就是問問題,弄清哪些是團隊明確的,哪些只是猜測。產品究竟是否可行?客戶是誰,怎么知道他們真正需要?時間線里哪些由物理法則決定,哪些受制于通用電氣內部流程? 緊接著該團隊介紹就X系列發動機已經批準的業務,其中有個收入預測圖,圖表中的曲線隨著時間一路向上,速度非常之快,仿佛這款還沒造出的發動機未來30年里每年真能賺數十億美元。貝斯·康斯托克回憶說:“感覺所有商業計劃里增長曲線都特別漂亮,好像五年就能漲到月亮上去,萬事俱備非常完美。” |

On a summer afternoon, a group of engineers and executives at one of America’s largest companies met in a classroom deep in the heart of their sprawling executive training facility to discuss their multi–$100 million, five-year plan for developing a new diesel and natural-gas engine. Their goal was to enter a new market space; excitement was running high. The engine, named Series X, had broad applications in many industries, from energy generation to locomotive power. All of this was very clear to those assembled in the room. Except to one person, who had no prior knowledge of engines, energy, or industrial product production and was therefore reduced to asking a series of questions Dr. Seuss might have posed: “What is this used for again? It’s in a boat? On a plane? By sea and by land? On a train?” The executives and engineers alike were no doubt wondering, “Who is this guy?” That guy was me. The company was GE, one of America’s oldest, most venerable organizations. I’m not a corporate executive. My background is not in energy or health care or any of GE’s myriad industrial businesses. I am an entrepreneur. But GE’s then–chairman and CEO Jeffrey Immelt and then–vice chair Beth Comstock had invited me to Crotonville, N.Y., that day because they were intrigued by an idea proposed in my first book: that the principles of entrepreneurial management could be applied to any industry, size of company, or sector of the economy. And they believed their company needed to start working according to those principles. The goal was to set GE on a path for growth and adaptability, to build a legacy that would allow the company to flourish long term. My journey to that meeting was an unlikely—not to mention unexpected—one. Early in my career I trained as a software engineer, after which I became an entrepreneur. If you’ve ever pictured a stereotypical tech entrepreneur as a kid, laboring away in their parents’ basement—well, that was me. My first foray into entrepreneurship, during the dotcom bubble, was an abject failure. My first published writing, 1996’s scintillating The Black Art of Java Game Programming, is, last time I checked, available used on Amazon.com for 99¢. None of these projects seemed like harbingers of future years that would be spent advocating for a new system of management. After I moved to Silicon Valley, though, I started to see patterns in what was driving both successes and failures. And, along the way, I started to formulate a model for how to make the practice of entrepreneurship more rigorous. Then I began writing about it, first online beginning in 2008, and then in a book, The Lean Startup, published in 2011. In the book, I made a claim that seemed radical at the time. I argued that a startup should be properly understood as “a human institution designed to create a new product or service under conditions of extreme uncertainty.” This definition was purposefully general. It didn’t specify anything about the size of the organization, the form it took (company, nonprofit, or other), or the industry or sector of which it was a part. According to this broad definition, anyone—no matter the official job title—can be cast unexpectedly into the waters of entrepreneurship. I argued that entrepreneurs are everywhere—in small businesses, mammoth corporations, health care systems, and schools, even inside government agencies. They are anywhere that people are doing the honorable and often unheralded labor of testing a novel idea, creating a better way to work, or serving new customers by extending a product or service into new markets. That idea helps explain why, for the past five years, I’ve been living a double life. I’ve had plenty of days when I met with the leader of a mammoth, market-leading organization in the morning and then, in the afternoon, spent time with startups—from massive hypergrowth Silicon Valley success stories to tiny seed-stage hopefuls. The questions I’m asked are amazingly consistent: How do I encourage the people who work for me to think more like entrepreneurs? How can I build new products for new markets without losing my existing customers? How can I create a culture that will balance the needs of existing business with new sources of growth? Learning from the companies I have been working with, I began to evolve a new body of work about principles that apply beyond the “getting started” phase, particularly in established and even large-scale enterprises. It’s about how traditional management and entrepreneurial management can work together. It is informed by case studies and wisdom from a variety of sources: iconic multinationals like GE and Toyota; established tech pioneers like Amazon, Intuit, and Facebook; the next generation of hypergrowth startups like Twilio, Dropbox, and Airbnb; and countless emerging startups you haven’t heard of—yet. Working with them, I have seen that entrepreneurship has the potential to revitalize management thinking in the 21st century. This is no longer just the way people work in one industry. It’s the way people everywhere work—or want to work. I call it the Startup Way. It was no accident that GE’s leaders had picked Series X as the first project to test. The thinking was that if we could get this huge, multiplatform engine project operating in a new way, there would be no limit to Lean Startup applications companywide, which aligned perfectly with the company’s desire to simplify its way of working across its many businesses. Hours after my first meeting in Crotonville, I found myself in a business school–type classroom elsewhere in the building, along with engineers representing the businesses involved in the Series X engine development, the CEOs of each of those businesses, plus a small cross-functional group of top-level executives who had orchestrated my visit. We had gathered to try to answer one of Jeff Immelt’s most persistent questions: “Why is it taking me five years to get a Series X engine?” I kicked off the workshop by asking the Series X team to walk us through their five-year business plan. My role was to ask questions about what the team actually knew vs. what they had guessed. What do we know about how this product will work? Who are the customers, and how do we know they will want it? What aspects of the timeline are determined by the laws of physics, vs. GE’s internal processes? The team proceeded to present the currently approved business case for the Series X, including a revenue forecast with graph bars going up and to the right with such velocity that the chart showed this as-yet-unbuilt engine making literally billions of dollars a year as far into the future as 30 years hence. Beth Comstock recalls: “It was like all the business plans we see, with a hockey stick that is going to grow to the moon in five years, and everything is going to be perfect.” |

|

但只要深挖一點,當然就會發現沒那么簡單。但最大的問題還是:為什么開發這款發動機要那么久? 我不想刻意降低其中面臨的技術挑戰:新產品需要巨大的工程量,還要遵從復雜的設計參數,要符合新的量產工廠和全球供應鏈需要。很多聰明人做了大量工作,才能確保計劃可行,技術準備充分。 但技術上面臨困難主要還是規范。這款產品得支持多種環境下的各種用途(想象下在海上、固定鉆井、火車、發動機和移動水壓開采時,對發動機要求必然不一樣)。各種用途基于對一系列市場、競品以及財務收益的假設,還要同時支持很多客戶。 各種“需求”都是采用傳統市場調研技術收集。但調研和焦點團體法并非實驗室里做實驗。客戶對自己要什么并不是總清楚,雖然經常很愿意提要求。雖然要為同一產品多類客戶服務,也并不意味著非這么做不可,也許可以想辦法縮短生產周期。 關于計劃里的商業假設也有很多問題。在座高管之一,時任通用電氣全球創新和新型號執行董事的史蒂夫·里果利回憶稱,“我們對市場和客戶有一系列深信不疑的假設。客戶希望獲得多少百分點的收益?是直接賣還是出租?經銷渠道要不要花錢?這種問題有幾十個,我們問這個團隊時發現24個問題只能答上兩個。”里果利稱這時才有點“眉目”。大家一直盯著技術風險,即產品能不能造出來,卻忽略了推廣和銷售風險,即這款產品到底該不該研發? 測試市場最好的方式就是直接把產品拿去問客戶,當天我就提出了非常激進的建議:先造出MVP柴油發動機。所謂MVP是指“最簡化可行產品”,也是在《精益創業》中談過的。MVP產品里只有剛好能滿足早期用戶的功能,可以迅速造出,小規模可控地投放,隨后收集反饋供下一步產品開發借鑒。 X系列發動機團隊總想著造出能在多種環境下工作的設備。結果是項目涉及層面多,受到預算和政治環境各種限制。如果先針對某種具體場景造一款簡單產品出來,將復雜問題簡單化呢? 房間里立刻議論紛紛。工程師表示做不到。有個人還說了個笑話:“也不是完全沒可能,我可以去競爭對手那買一款發動機,涂上商標再把我們的貼上去。”響起一陣尷尬的笑聲。 當然了,他們不會真去做,不過開玩笑之后他們談起五大用途中哪個最容易實現。海上使用得防水,移動水壓開采得有輪子,最后團隊認為固定發電機用的技術上最簡單。一位工程師認為研發周期可從五年減至兩年。 “從五年減到兩年,進步很大,”我說。“不過別滿足,我們繼續。新時間線上,造出第一臺發動機要多久?”此問題再次引起一些不滿之聲。有些參與者開始不厭其煩地向我解釋大規模量產的經濟性。不管后續造多少產品,建工廠和供應鏈花的時間差不多。 我再次表示抱歉:“請原諒我的無知,但我問的不是一條發動機生產線,而是造出一臺發動機需要多久?應該有測試機生產流程的是吧?”確實有,第一臺原型機要在一年內完成制造和測試。我問大家會不會有客戶對原型機感興趣,一位副總裁突然說,“有個客戶每個月都來我辦公室想買。我很確定他們會愿意買。” 房間里的氣氛頓時有點轉向。現在新產品交到客戶手上從五年減到一年了。不過團隊討論還在繼續。“如果向特定客戶出售一臺發動機的話,”一位工程師說,“我們都不用造全新的出來,可以把現有的產品改一改。”所有人都一臉驚愕盯著他。原來通用電氣一款叫616的產品只要稍微改動,就能符合發電設備的需要。 新款MVP比起原計劃,速度簡直快太多:從五年多變成不到六個月。只花了幾小時,也就問了幾個簡單的問題,我們就將項目時間大為縮短,還推動團隊迅速學習。如果他們愿意繼續這種思路,可能會為企業節省數億美元。如接下來問題還有很多。萬一啟動客戶不想買MVP了呢?萬一因為服務和支持網絡不夠力度,訂單非常少呢?現在發現問題難道不比五年后發現好么? 老實說:我非常興奮。看起來結果非常好。 事實真的如此么?研討會結束時,一位坐在后面的高管再也忍不住了。他問道,“向一位客戶賣一臺發動機到底有什么意義?”在他看來,我們從討論可能價值數十億的項目轉為討論毫無意義的小生意。他繼續說:即便撇開賣一臺發動機這種無稽之談,但只針對一位客戶的需求會將產品的目標市場減少80%。對這筆投資的回報率影響怎么算? 接下來發生的事我會永遠記得。“你說得對,”我說。“如果我們不需要學習,如果你仍然堅信之前的計劃,參與者的預測也跟幾分鐘前毫無變化,那么我說的就全都是廢話。測試就是暫時擺脫實際執行計劃,重新看待問題。”不騙你,那位高管立刻一臉信服。 本來我在通用電氣的工作可以就此結束,不過好幾位高管堅持讓我留下。大家開始討論起制造MVP可能出岔子的地方:如果客戶的需求不一樣怎么辦?如果設備需要的服務和支持比預想中復雜怎么辦?如果客戶使用的環境更艱苦怎么辦?如果新市場中客戶不信任我們的品牌怎么辦? 當談話從“這個外人怎么想?”轉為“我們自己怎么想?”情況就完全不一樣了。 馬克·里特爾時任通用電氣全球研究部門高級副總裁兼首席技術官,也是在場所有工程師最尊敬的人,他之前明確表示懷疑,讓工程師們很擔心。研討會結束時,他的話也讓所有人驚訝:“我明白了,問題在我。”他深切理解了企業行動要更迅速,意味著他跟其他領導者也要跟著適應。產品制造的標準流程拖慢了企業增長,作為流程負責人,他也要做出改變。 里特爾回憶說,“最重要的就是研討會改變了團隊的態度,從害怕犯錯變成積極投入,勤奮思考而且用于承擔風險愿意嘗試,管理團隊不再擔心出錯,而是想著驗證假設。思路真的放開了。” X系列發動機團隊由此變成通用電氣的先鋒項目之一,后來統稱為FastWorks。團隊迅速將測試發動機投入市場,很快獲得五臺發動機訂單。期間他們按照傳統流程持續研發,一邊等待著馬克·里特爾說的“大爆發”,通過MVP他們收集了市場意見,也獲得了收入。 還有很重要的一點要提一下。研討會期間,還有之后幾個月里,并沒有人給工程師們發號施令。我沒有,貝斯·康斯托克沒有,馬克·里特爾沒有,甚至杰夫·伊梅爾特也沒有。只要提供正確的思維框架,重新思考原先的假設,工程師們通過分析思考就提出了全新方案。很明顯,當時在場所有人都認為這種方法可行,團隊也獲得了理想結果,換個方式都是做不到的。 之所以通用電氣能在如此發展階段實現自上而下改變,是因為正是銳意進取積極變革的人在努力推動。我講的這個故事是親眼所見。但這不只是通用電氣的故事。其核心在于,勤奮努力的創始人可以在內部推廣創業精神,促進企業發展。每家企業都有可資借鑒的工具,真正利用起來需要的只是勇氣。 (財富中文網) 本文改編自《創業之術:現代企業如何利用創業式管理促進企業文化轉型并推動長期發展》。版權歸埃里克·里斯所有,出版社Currency和企鵝蘭登書屋。 本文另一版本將刊登于2017年11月1日《財富》雜志,標題為《讓巨頭像新創企業一樣思考》。 譯者:馮豐 審稿:夏林 |

Things got more complicated, of course, as we dug deeper. But the biggest question looming over the room remained: Why does it take so long to build this engine? I don’t want to undersell the technical challenges involved: The specifications required an audacious engineering effort that combined a difficult set of design parameters with the need for a new mass-production facility and global supply chain. A lot of brilliant people had done real, hard work to ensure that the plan was feasible and technically viable. But a large part of the technical difficulty was driven by the specifications themselves. Remember that this product had to support multiple distinct uses in very different physical terrains (visualize how different the circumstances are at sea, in stationary drilling, on a train, for power generation, and in mobile fracking). The uses were based on a series of assumptions about the size of the market, competitors’ offerings, and the financial gains to be had by supporting many different customers at once. These “requirements” had been gathered using traditional market-research techniques. But surveys and focus groups are not experiments. Customers don’t always know what they want, though they are often more than happy to tell you anyway. And just because we can serve multiple customer segments with the same product doesn’t mean we have to. If we could find a way to make the technical requirements easier, maybe we could find a way to shorten the cycle time. There were also many questions about the plan’s commercial assumptions. One of the executives present, Steve Liguori, then GE’s executive director of global innovation and new models, recalls, “We had a whole list of these leap-of-faith assumptions around the marketplace and the customer. What percentage gains is the customer looking for? Are you going to sell it or lease it or rent it? Are you going to pay for distribution? We had about two dozen of these questions, and it turns out that when we asked the team how many they thought they could answer, it was only two of the 24.” Liguori recalls this as the “aha moment.” The company had been so focused on the technical risks—Can this product be built?—that it hadn’t focused on the marketing and sales-related risks—Should this product be built? Since the best way to test market assumptions is to get something out to customers, I made what was, to the room, a really radical suggestion: an MVP diesel engine. The MVP, or “minimum viable product,” is a concept I explored in The Lean Startup. An MVP is a product with just enough features to satisfy early customers; producing one quickly, and making it available in a small, controlled way, can generate feedback that guides the next steps in a product’s development. The Series X team was trying to design a piece of equipment that would work in multiple contexts. As a result, it was caught up in the budgeting and political constraints that accompany such a multifaceted project. What would happen if we decided to target only one use case at first and make the engineering problem easier? The room went a little wild. The engineers said it couldn’t be done. Then one of them made a joke: “It’s not literally impossible, though. I mean, I could do it by going to our competitor, buying one of their engines, painting over the logo, and putting ours on.” Cue the nervous chuckles. Of course, they never would have actually done this, but the joke led to a conversation about which of the five uses was the easiest to build. The marine application had to be waterproof. The mobile fracking application needed wheels. Ultimately, the team arrived at a stationary power generator as the simplest technical prospect. One of the engineers thought this could cut their cycle time from five years to two. “Five years to two is a pretty good improvement,” I said. “But let’s keep going. In this new timeline, how long would it take to build that first engine?” This question seemed to once again cause some irritation in the room. The participants started to painstakingly explain to me the economics of mass production. It’s the same amount of work to set up a factory and supply chain, no matter how many engines you subsequently produce. I apologized once again: “Forgive my ignorance, but I’m not asking about one line of engines. How long would it take you to produce just one single unit? You must have a testing process, right?” They did, and it required that the first working prototype be done and tested within the first year. When I asked if anyone in the room had a customer who might be interested in buying the first prototype, one of the VPs present suddenly said, “I’ve got someone who comes into my office every month asking for that. I’m pretty sure they’d buy it.” Now the energy in the room was starting to shift. We’d gone from five years to one year for putting a real product into the hands of a real customer. But the team kept going. “You know, if you just want to sell one engine, to that one specific customer,” said one engineer, “we don’t even need to build anything new. We could modify one of our existing products.” Everyone in the room stared in disbelief. It turned out that there was an engine called the 616 that, with a few adjustments, would meet the specs for just the power generation use. This new MVP was literally an order of magnitude faster than the original plan: from more than five years to fewer than six months. In the course of just a few hours—by asking a few deceptively simple questions—we had dramatically cut the project’s cycle time and found a way for this team to learn quickly. And, if they decided to pursue this course, we could potentially be on track to save the company millions of dollars. What if it turned out that that first customer didn’t want to buy the MVP? What if the lack of a service and support network was a deal killer? Wouldn’t you want to know that now rather than five years from now? I’ll be honest: I was getting pretty excited. It seemed like a perfect ending. Or was it? As the workshop wound to its conclusion, one of the executives in the back of the room couldn’t stand it anymore. “What is the point,” he asked, “of selling just one engine to one customer?” From his point of view, we had just gone from talking about a project potentially worth billions to one worth practically nothing. His objections continued: Even putting aside the futility of selling only one engine, targeting only one customer use effectively lowered the target market for this product by 80%. What would that do to the ROI profile of this investment? I’ll never forget what happened next. “You’re right,” I said. “If we don’t need to learn anything, if you believe in this plan and its attendant forecast that we looked at a few minutes ago, then what I’m describing is a waste of time. Testing is a distraction from the real work of executing to plan.” I kid you not—this executive looked satisfied. And that would have been the end of my time at GE, except for the fact that several of his peers objected. The executives themselves started to brainstorm all the things that could go wrong that might be revealed by this MVP: What if the customer’s requirements are different? What if the service and support needs are more difficult than we anticipate? What if the customer’s physical environment is more demanding? What if the customer doesn’t trust our brand in this new market segment? When the conversation shifted from “What does this outsider think?” to “What do we, ourselves, think?” it was a whole new ball game. Mark Little, who was then senior vice president and chief technology officer of GE Global Research, was the person the engineers in the room most looked up to, and whose skepticism—voiced quite clearly earlier in the day—had them most worried. He ended our workshop by saying something that stunned the room: “I get it now. I am the problem.” He truly understood that for the company to move faster, he, along with every other leader, had to adapt. The standard processes were holding back growth, and he, as a guardian of process, had to make a change. “What was really important,” Little recalls, “was that the workshop changed the attitude of the team from one of being really scared about making a mistake to being engaged and thoughtful and willing to take a risk and try stuff, and it got the management team to think more about testing assumptions than creating failures. That was very liberating.” The Series X team turned into one of the many pilot projects for the GE program we came to call FastWorks. The team got the test engine to market dramatically sooner and immediately got an order for five engines. During the time they would have been doing stealth R&D in the conventional process, waiting for what Mark Little calls “the big bang,” they were gaining market insights and earning revenue from their MVP. I want to dwell on an important fact. During this workshop—and the months of coaching that followed—no one had to tell these engineers what to do. Not me, not Beth Comstock, not Mark Little, not even Jeff Immelt. Once presented with the right framework for rethinking their assumptions, the engineers came up with the new plan through their own analysis and their own insights. It became obvious to everyone in the room that this method had worked and that the team had arrived at an outcome that the company would not have been able to get to any other way. The reason GE was able to tackle changes at this level, at this stage, was because the transformation was driven very early on by people completely dedicated to making it happen. I’ve told you this story because it’s one I saw firsthand. But it’s not only a story about GE. It’s about how dedicated founders are the engine that powers entrepreneurship within an organization. Every company has levers that make it run. All it takes to pull them is courage.?? Adapted from The Startup Way: How Modern Companies Use Entrepreneurial Management to Transform Culture and Drive Long-Term Growth. Copyright ? 2017 by Eric Ries. Published by Currency, an imprint of Penguin Random House LLC. A version of this article appears in the Nov. 1, 2017 issue of Fortune with the headline “Teaching a Tech Giant to Think Like a Startup.” |